Guidance

4200

- Reduce overlap and minimize skips ensuring precise placement of crop protectants and nutrients

- Reduce product overlap by approximately 4.3 percent

- Improve performance with tuning, plant-to-row, and boundary features

- Reduce operator fatigue so they can stay in the field longer

*Based on independent university study of results with and without Section Control.

Results will vary based on conditions, planter size and type.

AutoPath™

- Use data from the first pass, either strip-till or planting, to automatically create full-field guidance lines for secondary passes such as planting, spraying, and harvest

- Setup time for secondary operations is faster and crop damage is reduced as guidance is based on actual planted crop rows

- Know which rows to start on, regardless of equipment width, even in down crops

- Available as part of the Automation 4.0 Package and Advanced License.

AutoTrac™

- Focus more on job quality and less on steering

- Keep original operator station ergonomics with a truly integrated experience

- Reduce skips and overlaps even on machines without factory installed AutoTrac

- Available on a wide variety of tractors, from utility tractors to articulated 4-wheel drives

- Choose the level of accuracy that fits your needs – SF1, SF3, or RTK

Automation 4.0 Activation

- Use data from planting – or strip till and planting – to automatically create full-field guidance lines for secondary passes

- Let AutoTrac™ Turn Automation take over your turns, implement functions, and speed

- Crush harvest chaos through combine and grain cart controls with Machine Sync

- AutoTrac™ Implement Guidance places your tool exactly where it needs to be, even on sidehills and around curves

G5

- Optional factory-installed on select 2024 and later models with CommandCenter controls

- 3x faster processor than previous models, for quicker cold boot times

- Large, 10.1-inch touchscreen with 1080p HD resolution – 35% larger than previous models

- Base includes Data Sync, Documentation, Over-the-Air Updates, and Remote Display Access

G5Plus

- Optional factory-installed on select 2024 and later models with CommandCenter controls

- Our largest display ever – 12.8-inch touchscreen with 1080p HD resolution

- 3x faster processor than previous models, for quicker cold boot times

- Base includes AutoTracTM, Section Control, Data Sync, Documentation, Over-the-Air Updates and Remote Display Access

John Deere Operations Center™ PRO Golf

- Total course management software with a real-time view of daily operations

- John Deere PRO Golf allows you to keep track of staffing and crew hours, equipment maintenance schedules, irrigation costs and more

- Manage labor, monitor the fleet, stay on top of maintenance schedules, and more

- Accessible from any device with an internet connection

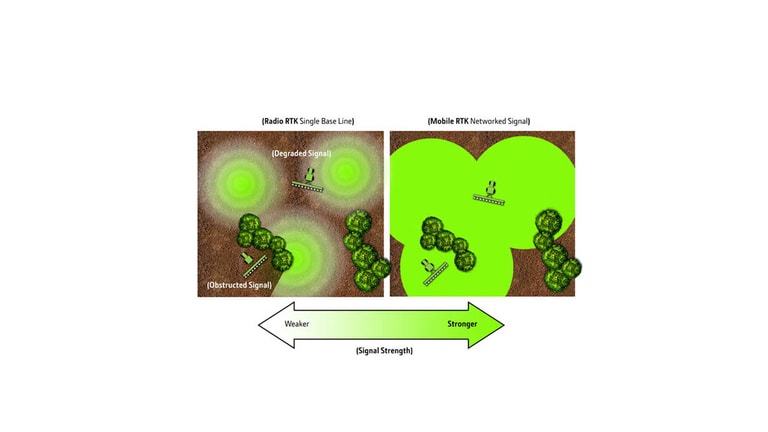

RTK Mobile

- Provides +/- 1 inch pass-to-pass accuracy season after season, and year after year

- Allows you to use RTK precision in difficult areas such as hilly terrain because there is no line-of-sight requirement to the base station.

- No need to manually switch base stations as you move between fields — you can roam anywhere within the network and have access to the RTK correction signal.

- Requires a StarFire 6000 receiver, SF3 Ready Activation, RTK Ready Activation

- Requires John Deere Mobile RTK subscription

Radio RTK 450

- Provides +/- 1 inch pass-to-pass accuracy season after season, and year after year

- Use a Dealer-owned RTK network to reduce your administrative expenses

- Provides less chance of radio interference, and RTK Extend to minimize shading signal loss

- Requires a StarFire 6000 receiver, SF3 Ready Activation, and RTK Ready Activation

- Requires RTK subscription provided by your John Deere dealer or your own base station

Radio RTK 900

- Provides +/- 1 inch pass-to-pass accuracy season after season, and year after year

- Use a Dealer-owned RTK network to reduce your administrative expenses

- Provides less chance of radio interference, and RTK Extend to minimize shading signal loss

- Requires a StarFire 6000 receiver, SF3 Ready Activation, and RTK Ready Activation

- Requires RTK subscription provided by your John Deere dealer or your own base station