John Deere 2633VT

2633VT Vertical Tillage

- Gang angle 21° Front/19° Rear

- Working Widths from 20'9" to 40'8"

- Operating Speeds 7-10 mph

- TruSet™ Active improves tillage depth accuracy and makes adjustments for varying field conditions, such as tire sink in soft soils or residue build up on tires, with no need for operator input

Features

Ground-engaging components on 2633VT

Ground-engaging components on 2633VT

2633VT pulled by 8370RT

2633VT pulled by 8370RT

The John Deere 2633VT offers six different sizes to fit any size operation, big or small.

| Model | 2633VT |

| Purpose | Vertical tillage |

| Working depth | Up to 75 mm (3 in.) |

| Standards | C-spring |

| Gang angle | 21 degrees front 19 degrees rear |

| Front gang blades |

|

| Rear gang blades | 560 mm x 5 mm (22 in. x 0.197 in.) solid shallow concavity 13 wave |

| Blade spacing | 185 mm (7.25 in.) |

| Gang bolt | 50 mm (2 in.) |

| Horsepower | 27 to 36 hp/m (8.5 to 11 hp/ft) |

| Working widths | 6.3 m to 12.4 m (20 ft, 9 in. to 40 ft, 8 in.) |

| Operating speed | 11 to 16 km/h (7 to 10 mph) |

Size |

6.3 m |

8 m |

8.9 m |

9.3 m |

10.2 m |

12.4 m |

Weight |

6796 kg |

9060 kg |

9230 kg |

9920 kg |

10025 kg |

12991 kg |

Number of blades |

68 |

88 |

96 |

104 |

112 |

136 |

Weight per blade |

100 kg |

103 kg |

96 kg |

95 kg |

90 kg |

95 kg |

Horsepower requirement |

131.2-170 kW |

164.8-213.3 kW |

184.2-237.9 kW |

196.1-254.3 kW |

208.8-270.7 kW |

259.5-335.6 kW |

Transport height |

3.05 m |

3.90 m |

4.30 m |

4.21 m |

4.62 m |

3.75 m |

Transport width |

4.11 m |

4.11 m |

4.11 m |

4.77 m |

4.77 m |

4.95 m |

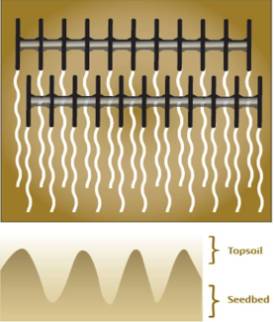

John Deere's 2633VT comes equipped on 185-mm (7.25-in.) spacing with solid shallow concavity spherical blades on the front gang and solid shallow concavity wavy blades on the rear gang to size residue and mix soil.

Most of the sizing is going to be done by the front gang, and the rear gang is going to do the mixing. John Deere designed its vertical tillage tool to chop stalks to an acceptable size and begin soil mixing for breakdown yet leave a considerable amount of residue on the cover.

The 2633VT comes equipped with 185-mm (7.25-in.) spacing on the front and rear gang. Both blade sizes on front and rear gang are 560 mm x 5 mm (22 in. x 0.197 in.). Optional 560-mm x 6.5-mm (22-in. x 0.256-in.) blades are available on front gang only.

Front solid shallow concavity spherical blade

Solid shallow concavity spherical blade

Solid shallow concavity spherical blade

- Chops and sizes residue

- Manages weeds

- Manages root balls

- Removes field ruts

Rear solid shallow concavity wavy blade

Solid shallow concavity wavy blade

Solid shallow concavity wavy blade

- Mix soil and residue

- Aerates soil

- Anchors residue

Front and rear 185-mm (7.25-in.) spacing

185-mm (7.25-in.) blade spacing

185-mm (7.25-in.) blade spacing

- Ideal for seedbed preparation

- Maximizes chemical incorporation

| Blade type | Solid spherical blade | Solid wavy blade |

| Thickness |

|

5 mm (0.197 in.) |

| Concavity | Shallow | Shallow |

| Diameter | 560 mm (22 in.) | 560 mm (22 in.) |

| Recommended soil types | All soil types | All soil types |

51-mm (2-in.) gang bolts

51-mm (2-in.) gang bolts

Gang tension system

Gang tension system

The John Deere 2633VT Vertical Tillage tool provides an innovative approach to tension gang bolts.

Overview

With short windows of time to perform tillage operations, TruSet provides significant productivity improvements as operators can adjust the tool with just the push of a button, maximizing acres covered per day. By responding to conditions as they change throughout the field, TruSet Active enables operators to generate a higher-quality tillage performance within the first pass.

Using a GreenStar™ display, an operator sees real-time data for a variety of feature settings, ensuring confidence in desired tillage outcomes. Four customizable presets enable operators to save and name different combinations of settings for their most common field conditions, which allows for even quicker implement adjustments.

TruSet allows for adjustments from the cab

TruSet allows for adjustments from the cab

TruSet Tillage system

TruSet Tillage system

Single-point depth control is included with the TruSet Tillage system, giving operators the choice of automated or manual adjustments. Hydraulic routings on the tool are designed to allow each implement to feature both TruSet and standard single-point depth control for system redundancy, operator preference, and flexibility at resale.

John Deere has expanded TruSet features to bring even more functionality into the cab:

- Active depth, and basket pressure and raise

- Gang angle

- Hydraulic active stabilizer wheels

- Hydraulic wing control

- Hydraulic fore-aft control

TruSet features and packages

TruSet Tillage features a variety of technology features and packages. With either the Select or Premium package, you can elevate your experience with some or full control of your tillage tool from the cab at your fingertips. The following table outlines each TruSet offering specific to the implement model. For additional information on each feature, see the details after the table.

| TruSet Functions | ||||||||

| Models: | Set-point depth | Active depth | Basket pressure | Side-to-side leveling | Gang angle | Fore-aft | Wing down pressure | Stabilizer wheels |

| 2230 Floating Hitch Field Cultivator | --- | Select** | Select | Premium | --- | --- | --- | --- |

| 2230 Level-Lift™ Field Cultivator | --- | Select** | Select | --- | --- | --- | --- | --- |

| 2330 Mulch Finisher | --- | Select** | Select | Premium** | --- | Premium** | --- | --- |

| 2630 Series Disks | --- | Select** | Select | Premium | --- | Premium** | --- | Option |

| 2633VT Vertical Tillage | --- | Select** | Select | Premium | --- | Premium** | --- | --- |

| 2660VT Vertical Tillage 1-Section 4.27 m (14 ft) | --- | Select** | Select | Premium | Premium | Premium | --- | --- |

| 2660VT Vertical Tillage 3-Section 7.8, 9.2, 10.1 m (25.5, 30.3, 31.10 ft) | --- | Select** | Select | Premium | Premium | Premium | Premium | Option |

| 2660VT Vertical Tillage 5-Section 14.1, 15.1 m (43.6, 49.6 ft) | --- | Select** | Select | --- | Premium | Premium | --- | Option |

| 2680H High-Speed Disk* | In base | --- | --- | --- | --- | --- | --- | --- |

| 2430C | --- | Select** | --- | Premium | --- | --- | --- | --- |

| 2430 Drawn Chisel Plow | --- | Select** | Select | Premium | --- | --- | --- | --- |

*Currently not available in feature packaging

**New feature

NOTE: All Select package features are also included in the Premium package.

Active depth (Select and Premium package)

Adjust depth and pressure while in the field

Adjust depth and pressure while in the field

- With TruSet Active, the tillage tool automatically adjusts and keeps the desired depth even through changing field conditions, such as tire sink in soft soils or mud buildup in damp and sticky conditions.

- This is possible using an ultrasonic sensor that measures the distance from the mainframe to the soil as the implement travels through the field.

Basket pressure and raise (Select and Premium package)

- Integrated TruSet Tillage technology enables the operator to adjust their down pressure on the hydraulic rolling baskets while on the go to respond to changing field conditions such as varying soils, heavier residue, and moisture.

- Easily raise your baskets with one touch to avoid certain areas of the field, whether you are wanting to check the tillage tool with the baskets up or avoid going through a wet spot in the field. Once you’re through the area and ready to lower the baskets, simply press the basket lower to resume your desired basket pressure.

Side-to-side leveling (Premium package)

Individual section leveling with TruSet side-to-side

Individual section leveling with TruSet side-to-side

- Operators have the option to enhance the TruSet Tillage system with individual section leveling functionality. TruSet side-to-side is available as a field-installed option that can be ordered with the tillage tool or through aftermarket parts. The base TruSet Tillage system can also be upgraded to TruSet side-to-side with a conversion kit.

Gang angle (Premium package)

Gang angle adjustment

Gang angle adjustment

- With TruSet gang angle control, operators can adjust the gang angle on the go right from the cab. Adjusting the gang angle from 0 to 12 degrees provides more horizontal soil movement. The more aggressive the gang angle, the more soil mixing and burying of residue. Operators can also remove light ruts, tracks, and weeds at the most aggressive gang angle.

Fore-aft (Premium package)

Hydraulic fore-aft control levels the 2660VT

Hydraulic fore-aft control levels the 2660VT

- TruSet hydraulic fore-aft control enables operators to level the implement from the comfort of the tractor cab.

Wing down pressure (Premium package)

TruSet documentation

With integrated TruSet Tillage technology, operators can incorporate documentation and prescription functionality into their tillage operations. The tillage documentation feature allows producers to capture and analyze the tillage pass for additional coverage of the crop production cycle. Prescription functionality provides producers the capability to ensure their tillage operations are executed correctly, optimizing their investment in preparing for the next crop.

Operators can document data for the depth of their tillage tool along with rolling basket down pressure. By creating an as-applied map based off global positioning system (GPS) data for the job performed by each functional area on the implement, TruSet enables producers to document their tillage passes then later review and analyze the data for future agronomic decisions.

Additionally, the TELUS Agronomy Prescription Creator company, a connected partner tool through the John Deere Operations Center, enables producers to create prescriptions for each functional area on the tillage tools. Data from previous yields, soil surveys, or freehand drawing tools can be used to create prescriptions that command the implement to the desired depth and pressure settings for optimum agronomic results.

TELUS Agronomy Prescription Creator is a trademark of TELUS Agriculture and Consumer Goods

Hydraulic wing control pressure

Hydraulic wing control pressure

- TruSet hydraulic wing control transfers the weight from the mainframe to the wings to improve penetration in hard or heavy soils. In high-speed, shallow-depth tillage operations, maintaining a consistent depth across the tillage tool is critical to the consistency of the seedbed.

NOTE: TruSet hydraulic wing control pressure is only offered on three-section models.

Stabilizer wheels (additional factory option)

- Getting the best field performance is easier with TruSet Active hydraulic stabilizer wheels. Choose the option to easily adjust the depth of the stabilizer wheels from the cab to match the overall depth as changes are made. This feature replaces the mechanical linkage on stabilizer wheels with a hydraulic cylinder.

NOTE: Stabilizer wheels are not offered on one-section models.

Residue management

Residue management

Whether the plan is to use the 2633VT in the spring or fall, this machine was designed to handle any residue management situation. With a 21-degree angle on the front gang and 19-degree gang angle on the rear gang, this tool was created to have aggressive sizing and chopping ability in tough residue in the fall and to have finishing characteristics to build an ideal seedbed in the spring.

Shallow gang angle

Shallow gang angle

Aggressive gang angle

Aggressive gang angle

Shallow gang angle vertical tillage tools can leave a wavy, washboard effect unsuitable for a proper seedbed. The 2633VT implement has an aggressive gang angle to help anchor residue, manage weeds and root balls, and create an even, smooth seedbed under the topsoil.

As crop yields increase, so does the amount of residue after harvest. The John Deere 2633VT allows producers to prepare soil for planting in the spring and residue management in the fall.

Hydraulic rolling basket with down pressure

Hydraulic rolling basket with down pressure

Hydraulic rolling basket - in raised position

Hydraulic rolling basket - in raised position

The 2633VT offers active hydraulic rolling baskets that give the operator wide-ranging adjustability for a variety of conditions. The drawbars and rolling basket on the rear harrow are built with strength in mind for demanding vertical tillage conditions.

The system was designed to run the rolling baskets in three different positions:

- Raised

- Allows the operator to raise the rolling baskets in harsh, muddy conditions

- Float

- Allows the operator to float the rolling baskets to lightly fluff soil

- Apply down pressure

- Allows the operator to adjust the basket pressure to provide consistent contact with the ground

- Provides a firm seedbed

- Shatters root balls

The hydraulic rolling basket is offered with a round bar, or knife-edge. The knife-edge is best for heavier, wet soil.

With these rolling baskets, a cast frame was designed to encase the bearing in a high-density polymer liner to allow dynamic movement and maintenance-free characteristics. Similar to the gangs on the 2633VT, the active hydraulic rolling baskets feature maintenance-free bearings to minimize non-productive activities.

Hydraulic rolling basket down pressure valve

Hydraulic rolling basket down pressure valve

Hydraulic round bar rolling basket harrow

Hydraulic round bar rolling basket harrow

Hydraulic knife-edge rolling basket harrow

Hydraulic knife-edge rolling basket harrow

To change the rolling basket down pressure, simply rotate the down pressure valve dial clockwise to increase pressure and counterclockwise to decrease pressure.

John Deere 2630 Series Disks and Vertical Tillage Implements feature extended-life bearings. These more durable and reliable bearings allow producers to customize bearing maintenance for specific growing conditions and soil types.

The flange-mounted bearing and sealing system features improved contamination resistance. The advanced seal material is highly resistant to wear and damage caused by abrasive soils and other crop materials. The design of these is more durable and reliable than previous bearings.

The design of this bearing system allows for dynamic self-alignment to the gang bolt, as opposed to trunnion-mounted bearings that have limited alignment capability. This system features additional freedom of movement, accommodating a wider variety of field conditions. The bearing system has been designed to decrease stress and fatigue on the inner rolling surfaces, supporting extended bearing life.

The bearing and seal design allows for a limited, seasonal maintenance interval to minimize downtime. They also allow producers to customize the maintenance for specific growing conditions and soil types. The multi-lipped sealing system cannot be damaged by frequent greasing. It allows bearings to accept grease within the bearing as well as provide grease to the outer bearing surface to eliminate wear between the bearing and housing. With this design, the bearings can accept grease even if misaligned to the housing.

2630 Disk in the field

2630 Disk in the field

2630 Disk in the field

2630 Disk in the field

The 2630 Series Disks offer multiple upgrades and additional items as options versus the 2620 Series Disks to enhance the machine. Check out the following video to see more about the 2630 Series Disks.

Extended-life bearings

John Deere 2630 Series Disks and Vertical Tillage Implements feature extended-life bearings. These more durable and reliable bearings allow producers to customize bearing maintenance for specific growing conditions and soil type.

TruSet™ side-to-side feature

John Deere TruSet system is featured in base equipment for the 2630 Series Disks and Vertical Tillage Implements. TruSet side-to-side is also available and features individual section leveling.

Knife-edge hydraulic rolling basket

The hydraulic rolling basket is offered with a round bar or knife-edge. The knife-edge is best for heavier, wet soil, and can be used in rocky conditions.

Radial tires

The 2630 Series Disks and Vertical Tillage Implements feature radial tires for the mainframes in base equipment. Radial tires are available as an option on the wing frame and stabilizer wheels. These tires are designed to offer longer wear life and help minimize compaction with a wider plate and lower inflation pressures.

Stabilizer wheels

Producers can choose either mechanical stabilizer wheels or TruSet hydraulic stabilizer wheels as an option. Stabilizer wheels help to maintain a consistent, level depth and are recommended for operation on rolling ground. The mechanical stabilizer wheels can be manually adjusted with a turnbuckle. TruSet with side-to-side leveling capabilities also enables operators to control the TruSet hydraulic stabilizer wheels from the cab while on the go.

Specs & Compare

Key Specs | 2633VT Current Model |

| Blade spacing | 18.4 cm 7.25 in. |

| Horsepower requirement | 193.5-236.8 kW 263-322 hp |

| Transport width | 4.2 m 13.67 ft |

| Transport height | 4.3 m 14.1 ft |

| Working depth | Up to 7.6 cm 3 in. |

| Operating speed | 11.4-16.1 km/h 7-10 mph |

Machine | |

| Standards | C-spring |

| Blade spacing | 18.4 cm 7.25 in. |

| Gang angle | Front: 21 degree (angle) Rear: 19 degree (angle) |

| Front gang blades | Solid shallow concavity spherical: 559x4.5 mm 22x0.197 in. |

| Rear gang blades | Solid shallow concavity 13 wave: 559x4.5 mm 22x0.197 in. |

| Weight | 9,227 kg 20,343 lb |

| Number of blades | 96 |

| Weight per blade | 95.7 kg 211 lb |

| Rolling basket | Round bar or flat bar (see note below) |

| Horsepower requirement | 193.5-236.8 kW 263-322 hp |

| Transport width | 4.2 m 13.67 ft |

| Transport height | 4.3 m 14.1 ft |

| Working depth | Up to 7.6 cm 3 in. |

| Operating speed | 11.4-16.1 km/h 7-10 mph |

| Note | Flat bar is not recommended for rocky soil conditions. |

| Commander™ blade diameter | |

| Commander™ blade thickness | |

| Depth control | |

| Maximum operating depth | |

| Transport length | |

| Underframe clearance | |

| Working width | |

Additional information | |

| Date collected |