John Deere STS12

Hagie™ Self-Propelled Sprayer

- 1200-gallon (4,543 L) tank

- Up to 132-foot (40.23 m) boom

- 300 hp, 9.0 L engine

- 35 mph (56.3 km/h) transport speed

Features

Hagie™ STS Sprayer in corn

Hagie™ STS Sprayer in corn

No matter the field or crop conditions, it is important to be able to feed and protect your crops throughout the entire growing season. The all-season capability and performance of the STS Sprayers enable you to enter the field any day.

- Gliding over crop with 1.88 m (74 in.) of underframe clearance combined with a narrow in-row crop package and smooth transition shields minimizes impact and crop disturbance.

- Standard AWS ensures the rear tires follow the front tires, leaving only two tracks while turning.

- Not only does the STS excel in late-season, tall-crop applications, but its balanced weight distribution with the tank full, empty, or anywhere in between and optional floatation tires enable it to perform in challenging field conditions all year long.

Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

PowrSpray solution keypad

PowrSpray solution keypad

Covering acres is important and doing so with accuracy and precision is essential. The PowrSpray solution control system found on the Hagie™ STS Sprayers makes sure every acre is covered precisely. The predictive pump control ensures target rates are accomplished faster, even in challenging dynamic conditions. Add the optional dedicated pull-on pump for fast and accurate solution tank loading and/or ExactApply™ for nozzle-by-nozzle control.

- Predictive pump control anticipates changes in flow to maintain target rate

- Electronic solution tank level indication

- Fast and accurate loading with the optional dedicated pull-on pump

- Optional eductor

- Optional ExactApply nozzle control

The solution keypad found on the cab entry ladder provides control of critical solution functions from the ground, eliminating the need to climb back into the cab during tending.

For operators that prefer the front fill location, there is an option to relocate the PowrSpray solution control system keypad to the front fill location for ease of utilizing the features offered on the keypad.

Dealer Use Only:

Code |

Description |

8925 |

Fill Control Keypad Relocation – Front Only one keypad location can be used at a time. The unused keypad will be unplugged and not operational. V437024 |

Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

Hybrid sprayer boom

Hybrid sprayer boom

Cover acres with confidence and control. The Hagie hybrid front boom lineup offers a lightweight yet durable design by combining both steel and aluminum. Strong steel composes the interior sections of these booms, providing strength and flexibility where you need it. The outer sections are made of aluminum, reducing overall weight and improving control. Special consideration for hose and plumbing routing improves operator visibility and overall boom cleanliness. Spray tips and nozzle bodies are protected from impact as they are positioned within the booms structure.

- Improved visibility and lighter overall weight than all-aluminum booms on previous-generation models

- Available in a range of widths and nozzle spacings

- Large range of application heights from 58.4 to 279.4 cm (23 to 110 in.)

- Three-direction, spring-applied outer breakaway

- Hydraulic main boom breakaway

- 18-m (60-ft) outer wing folded width on 27-, 30-, and 36-m (90-, 100-, and 120-ft) booms

- 21-m (70-ft) outer wing folded with on 40-m (132-ft)

- Locking connection between the inner and outer sections of the boom ensures rigidity

Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

Boom Update

The hydraulic cylinders have been updated along with surrounding structure to improve the folding and unfolding of the booms. The improved performance is especially beneficial when a drop system is installed.

The electronically controlled CommandDrive drive system provides an infinite range of field speeds and operator adjustability. The single hydrostatic drive pump provides flow to four variable displacement wheel motors. The system works automatically to continuously adjust they system to match target speed.

- Real time traction control – CommandDrive monitors for wheel slip and diverts oil flow to send power to the other wheels. This system monitors for slip front to rear, side to side, and crossways for maximum control and minimal slippage. Two predefined traction control settings are available (normal and severe) in addition to a custom setting that allows for manual control of both slip and de-stroke percentages.

- Operator programmable speed ranges – Select the number of speed ranges from 1 to 20 and the first and last range top speed. This allows the drive system to be tuned for operator preference and field conditions.

- Scroll wheel speed range selection – By scrolling the wheel on the back of the control handle, operators select the desired speed range. In addition to the scrolling feature, the scroll wheel can be pushed to rapidly change between spray and turn speed. Spray and turn speed can be set by the operator within the corner post display.

StarFire 7000 Integrated Receiver on Hagie™ STS Sprayers

StarFire 7000 Integrated Receiver on Hagie™ STS Sprayers

The StarFire 7000 Receiver is the latest addition to the suite of Precision Ag Technology from John Deere. The StarFire 7000 Receiver offers greater accuracy, faster pull-in times, and season-to-season repeatability. This means less hardware, faster times recovering from a shading event, and the confidence that your guidance lines and boundaries do not shift from year to year. The integrated design further enhances the value that you have come to expect from StarFire products.

Similar to the StarFire 6000 Integrated Receiver, the StarFire 7000 eliminates all setup, installation, and calibrations. There is no need to verify machine and receiver measurements, as this has been done precisely for you at the factory. You will spend 60 minutes less per receiver move each season, which gives you more time to focus on other parts of your operation.

With updated Ethernet connectivity, software updates are easier and faster. StarFire 7000 Integrated Receiver maintains the speed to update software in under 4 minutes while remaining in the cab. Over-the-air updates are 85 percent faster with the StarFire 7000 Integrated Receiver because of Ethernet connectivity.

Benefits to the StarFire 7000 with SF-RTK

- 5-year repeatability

- 10-minute pull-in time

- 2.5-cm (1-in.) pass-to-pass accuracy

- Drop-in replacement for StarFire 6000 Integrated Receivers

To learn more about the StarFire 7000, visit the StarFire 7000 page.

Cab with Ultimate Comfort and Convenience package

Cab with Ultimate Comfort and Convenience package

The Ultimate Comfort and Convenience package offers unsurpassed visibility, operator comfort, control placement, and ride and sound quality.

- Increased comfort from leather seat with massage, heating and cooling, electronic controls and better swivel

- Easily make adjustments on the go

- Improved visibility on the left and right with better sight lines to the crop

Vision leather seat

Vision leather seat

Heating, ventilation, and massage controls for Vision seat

Heating, ventilation, and massage controls for Vision seat

Electric position controls for Vision seat

Electric position controls for Vision seat

Vision leather seat

- Improved swivel seat – 16 degrees to the left and 16 degrees to the right

- Heated and ventilated cooling

- Massaging functions to reduce fatigue during long days in the field

- Electronic controls that make it easier to adjust the seat to the preferred location

- Pneumatic lumbar

- Cushion length adjust

ActiveSeat II

ActiveSeat II

ActiveSeat II

ActiveSeat II

ActiveSeat II

When spraying and transport conditions are not ideal, it is important that comfort is not sacrificed. With the Hagie’s Ultimate cab package, a seat suspension package is offered to improve spraying comfort even further. This seat provides the highest level of comfort during bumpy conditions and ensures operators will finish their long harvest days without aches and pains.

Redesigned using an electric motor for quicker response and a simplified design, the ActiveSeat II seat suspension option significantly reduces vertical motion of the operator up to 90 percent compared to the machine, ensuring a smoother ride than any seat suspension options offered by Hagie in the past.

Digital touchscreen radio

Digital touchscreen radio

Apple CarPlay® radio

The 16.5-cm (6.5-in.) state-of-the-art digital touchscreen radio works with Apple CarPlay and provides a multitude of entertainment options. CarPlay is a smarter, safer way to use an iPhone® mobile device when driving.

- Connect phone via Bluetooth® wireless or USB to play music

- Check the weather

- Navigation

- Phone calls

- Voice control

Door cinch with remote door opening

- Door cinch reduces the force needed to close the door

- Electric motor makes it easier to open and close the door without slamming

- Remote door opening and door lock-unlock fob

- Minimize residue exposure from outside surfaces by using the door fob to remotely open the door

CommandARM™ console and controls with display

CommandARM™ console and controls with display

4600 CommandCenter™ Display

- Improved visibility with 80 degrees of swivel to the right

Refrigerator

Refrigerator

Refrigerator

- Keep beverages and other items cool

Plenty of storage

- Three cup holders

- Easily accessible storage compartments located to the right and behind the seat

Footrest

Footrest

Bluetooth is a trademark of Bluetooth SIG, Inc. Apply CarPlay and iPhone are trademarks of Apple Inc.

Montag cover crop system

Montag cover crop system

Montag cover crop system

Montag cover crop system

Boost the versatility of the Hagie STS Sprayers and optimize soil health with a cover crop seeding solution. The Montag Fortifier 2212 Cover Crop System is an engineered solution specifically designed to be compatible with model year 2014 to 2021 Hagie STS12 Sprayers equipped with a 36.6-m (120-ft) hybrid boom.

Montag cover crop system with two bins

Montag cover crop system with two bins

The Montag cover crop system features a two-bin design totaling 4.4-m3 (155-cu ft) capacity, offering the highest cover bin capacity available on the market to improve uptime. The stainless-steel twin bin design equips producers with two-product application proficiency.

Montag cover crop system controls

Montag cover crop system controls

The unit comes standard with a Montag-developed ISOBUS rate controller and ISOBUS scales for optimal application accuracy. Operating on the standard Hagie hydraulic pump and offered with standard four-section control, metering augers ensure the highest possible row-to-row accuracy. Producers are also provided with the STS12 chassis hardware package to ensure system adaptability with the kit.

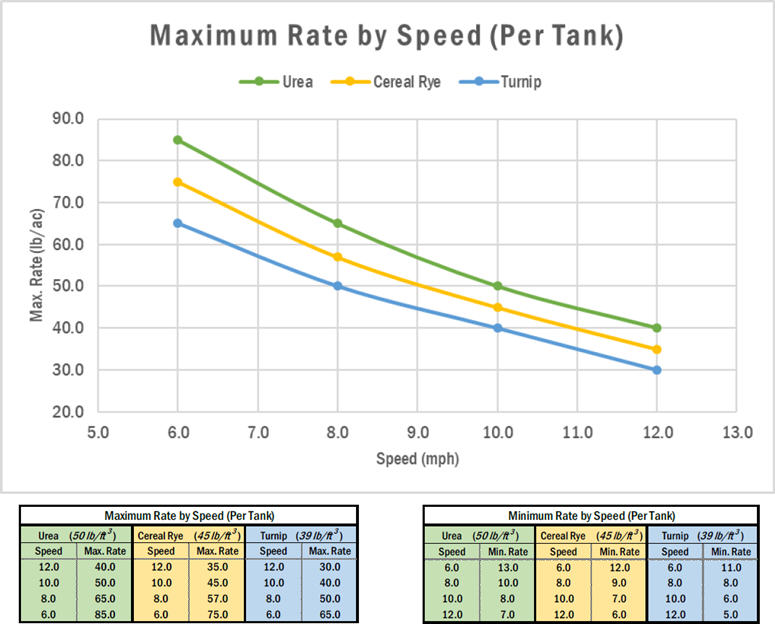

Maximum rate by speed per tank

Maximum rate by speed per tank

When performing seeding applications at 16.1 km/h (10 mph), producers can apply 7.3 kg to 40.8 kg (16 lb to 90 lb) of seed per acre to meet individual productivity needs. The only system offered today specifically designed for this purpose, the Montag Fortifier 2212 Cover Crop System provides a unique solution to protect and nurture soil health while enhancing versatility, making the Hagie STS a one-machine solution for full season application needs.

| Key specifications | |

| Rows | 12 rows (12 rows split to 48 rows [49 drops]) |

| Sections | Four sections |

| Product capacity | |

| Bin | 2,192 L (77.4 cu ft), 1,760 kg (1.94 tons) |

| Total | 4,383 L (154.8 cu ft), 3,511 kg (3.87 tons) |

| Rate capacity | |

| Bin | 9-56 kg/ha (8-50 lb/acre) |

| Total | 18-101 kg/ha (16-90 lb/acre) |

| Weight | 1,474 kg (3,250 lb) |

| Overall height | 193.8 cm (76.3 in.) |

| Overall length | 246.4 cm (97 in.) |

| Overall width | 212.1 cm (83.5 in.) |

| Product fill height | 374.1 cm (147.3 in.) |

| Product fill inlet size | 0.61 m2 (6.55 sq ft) |

| Meter outlet | 5.08 cm (2 in.) |

| Boom drop | 3.18 cm (1.25 in.) |

| Required hydraulic capacity | 95 L/min (25 gpm) |

| Required hydraulic pressure | 203 bar (2,950 psi) |

NOTE: Compatible with model year 2014 to 2021 Hagie STS12 with 36.6-m (120-ft) hybrid boom.

Montag Mfg. has an allied partnership agreement with John Deere as it relates to the cover crop system and is responsible for providing sales and technical support to dealers.

IMPORTANT: When you click this link, you will be leaving the Deere site. You will be directed to a non-Deere site. Such linked websites are not under the control of Deere. To the full extent permitted under applicable law, Deere is not responsible for the contents of any linked site or any link contained in a linked site. The inclusion of any link does not imply endorsement by Deere of the site, and Deere shall have no responsibility for information which is referenced by or linked to this site.

For additional information about the system, visit www.montagmfg.com or call 712-852-4572.

Montag is a trademark of Montag Manufacturing, Inc. Hagie is a trademark of Hagie Manufacturing Company and similar to John Deere branded equipment, John Deere will support Hagie equipment.

Specs & Compare

Key Specs | STS12 Current Model |

| Rated engine power | |

| Maximum engine power | |

| Solution system - Capacity | 4400 L 1200 gal. |

| Rinse tank capacity | 605 L 160 gal. |

| Boom length options/Material | Hybrid steel and aluminum: 18/27, 18/30, 18/36, or 21/40 m 60/90, 60/100, 60/120, or 70/132 ft |

| Spray speed range | 0.8 to 40 km/h 0.5 to 25 mph |

| Transport speed, maximum | 56 km/h 35 mph |

| Suspension | Independent air-ride |

| Crop clearance with standard tires | 188 cm 74 in. |

| Total weight (empty solution tank) | 11,906.4 kg 31,900 lb |

Engine | |

| Make | |

| Rated engine power | 221 kW 300 hp |

| Maximum engine power | |

| Power bulge | |

| Emissions | Final Tier 4 (FT4) |

| Number of cylinders | Six |

| Displacement | 9 L 548 cu in. |

| Transmission | |

| Alternator | 300 amp |

| Fuel tank capacity | 492 L 130 gal. |

| Diesel exhaust fluid (DEF) tank capacity | 29 L 7.7 gal. |

| AutoTrac speed, maximum | |

Solution system | |

| Capacity | 4400 L 1200 gal. |

| Tank material | Stainless steel |

| Rinse tank capacity | 454 L 120 gal. |

| Solution pump flow | |

| Quick fill size | 7.6 cm 3 in. |

| Rate control make | |

| Automatic section control | Optional |

| Display | |

| Solution system control | PowrSpray™ system |

| Fill location | Standard: Side Optional: Front |

| Fill pump flow | |

| Chemical injection method | Optional: Raven Sidekick |

| Chemical eductor | Optional |

| Chemical eductor capacity (size) | 19 L 5 gal. |

| Flow meter size | 5.8 cm 2 in. |

| Suction strainer | |

| Pressure strainer | 50 mesh |

| Boom strainer | Standard 80 mesh |

Boom | |

| Boom length options | Hybrid steel and aluminum: 18/27, 18/30, 18/36, or 21/40 m 60/90, 60/100, 60/120, or 70/132 ft |

| Automatic boom height | NORAC® UC7™ with Active Wing Roll (AWR) |

| Plumbing material | Stainless steel |

| Boom Material | |

| Ground height adjustment | 58 to 272 cm 23 to 107 in. |

| Breakaway width | For 27-m (90-ft) booms: 1.5 m 5 ft For 18/30 or 18/36 (60/100 or 60/120 ft): 3 m 10 ft For 40-m (132-ft) booms: 3.3 m 11 ft |

| Boom sections | On 27-m (90-ft) boom: 7 sections On 30-, 36-, and 40-m (100-, 120-, and 132-ft) booms: 9 sections m (100, 120 and 132 ft) |

| Nozzle spacings | |

Drivetrain | |

| Type | CommandDrive™ |

| Drive | Full-time four-wheel drive (4WD) |

| Shifting | Infinitely variable - Operator programmable |

| Hydraulic reservoir capacity | 113.5 L 30 gal. |

| Spray speed range | 0.8 to 40 km/h 0.5 to 25 mph |

| Transport speed, maximum | 56 km/h 35 mph |

Chassis | |

| Type | |

| Dry compatible | Montag® Fortifier |

| Suspension | Independent air-ride |

| Crop clearance with standard tires | 188 cm 74 in. |

| Front tires | VF320/105R54, VF380/90R54, VF380/105R50, VF420/95R50, VF480/80R50 |

| Rear tires | VF320/105R54, VF380/90R54, VF380/105R50, VF420/95R50, VF480/80R50 |

| Flotation tires | VF480/80R50, VF 620/70R46, IF710/65R46 |

| Hydraulic tread adjust | Standard |

| Wheel tread spacing | 305 to 406 cm 120 to 160 in. |

| Wheel base | 386 cm 152 in. |

| Turning radius | With all-wheel steer (AWS) on: 5.3 m 17.3 ft With AWS off (center of outside tire): 7.8 m 25.6 ft |

| Parking brake | Integrated in final drives |

| Primary brakes | Drive system dynamic braking |

| Ladder raise/lower | Hydraulic |

| Total weight with 80-ft boom | |

| Total weight with 90-ft boom | 14,333.5 kg 31,600 lb |

| Total weight with 100-ft boom | 14,288 kg 31,500 lb |

| Total weight with 120-ft boom | |

| Total weight with carbon fiber boom (empty solution tank) | |

| Total weight (empty solution tank) | |

Options | |

| Pressure washer | |

| Air compressor | Onboard air |

| Foam marker capacity | |

| Remote service tools | |

Additional information | |

| Date collected | 1 March 2021 |