John Deere 600R

Dry Spinner Spreader

- 200 or 300 cu. ft. (5.6 or 8.5 m3)dry box

- 375 hp, 9.0 L engine

- 25 mph (40.2 km/h) field speed, 35 mph (56.3 km/h) transport

- Integrated intelligence with StarFire™ receiver, JDLink™ connection, and more

- Three cab and visibility packages to customize your sprayer

Features

New Leader Dry Spinner Spreader on a 400R or 600R

New Leader Dry Spinner Spreader on a 400R or 600R

Get three-season flexibility from your application equipment with the New Leader DS20 or DS30 Dry Spinner Spreader.

The DS20 offers of up to 5.6-m3 (200 cu ft), or 6.6 tons, of dry fertilizer, while the DS30 bumps capacity to 8.5 m3 (300 cu ft), or 9 tons, of dry fertilizer. Both models feature:

- Four-hour conversion from a liquid-application setup

- Variable-rate application ranging from 34 kg/ha (75 lb/acre) to 3 tons/acre

- Spread width of up to 32 m (105 ft) thanks to the 1.83-m (72-in.) spinner height

- New Leader G4 spinner technology for a consistent spread pattern and more uniform application

- Available in single or the MultApplier (dual product bins) in both the 304 stainless or 409 painted spreader construction with #4 belt-over-chain conveyor

- The G4 remains the only option for being fully integrated with the John Deere SpreadStar™ dry rate control system.

- New Leader G4 Edge and G5 are being added into the dry portfolio for model year 2024 machines.

- Available in the 304 stainless steel single bin or the MultApplier (dual bin options). The MultiBin™ is not an available option currently.

- Both the G4 Edge and G5 box options on the 400 and 600 series will now offer the AgLeader ISO-VT dry rate controller.

Dry Spinner Spreader comparison chart

| New Leader box options - DS20/DS30 dry spinner spreader | |||

|

G4 |

G4 Edge |

G5 |

John Deere SpreadStar dry rate control system |

X |

|

|

New Leader ISO-VT dry rate control system |

|

X |

X |

Left hand and right hand spinner speed control boundary spreading |

|

X |

|

Precision independent spinner control monitoring |

|

X |

X |

16-section swath width control |

|

|

X |

1/2 width spreading |

|

X |

X |

Last pass control |

|

|

X |

Automatic feedgate and fan frame control |

|

|

X |

Centralized grease banks |

X |

X |

X |

Tarp ready |

X |

X |

X |

Automatic chain oiling routine and alarms |

X |

X |

X |

304 stainless steel |

X |

X |

X |

409 stainless steel |

X |

|

|

MultApplier compatible |

X |

X |

X |

Backup camera ready |

X |

X |

X |

| 400R and 600R dry spinner spreader | |

| New Leader G4 - | |

| 4800 | DS20 G4 - 304 stainless steel, single bin, #4 belt over chain, 13 cm (5 in.) feedgate |

| 4806 | DS20 G4 - 304 stainless steel, single bin, #4 belt over chain, 28 cm (11 in.) feedgate |

| 4808 | DS20 G4 - 409 painted steel, single bin, #4 belt over chain, 28 cm (11 in.) feedgate |

| 4818 | DS20 G4 - 409 painted steel, single bin, #4 belt over chain, 13 cm (5 in.) feedgate |

| 4820 | DS20 G4 - 304 stainless steel, MultApplier (dual bin), #4 belt over chain, 13 cm (5 in.) feedgate |

| 4814 | DS30 G4 - 304 stainless steel, single bin, #4 belt over chain, 13 cm (5 in.) feedgate |

| 4816 | DS30 G4 - 409 painted steel, single bin, #4 belt over chain, 13 cm (5 in.) feedgate |

| 4834 | DS30 G4 - 304 stainless steel, MultApplier (dual bin), #4 belt over chain, 13 cm (5 in.) feedgate |

| 400R and 600R dry spinner spreader | |

| New Leader G4 Edge - | |

| 4842 | DS20 G4 Edge - 304 stainless steel, single bin, #4 belt over chain, 28 cm (11 in.) feedgate |

| 4844 | DS20 G4 Edge - 304 stainless steel, single bin, #4 belt over chain, 13 cm (5 in.) feedgate |

| 4846 | DS20 G4 Edge - 304 painted steel, MultApplier (dual bin), #4 belt over chain, 13 cm (5 in.) feedgate |

| 4848 | DS30 G4 Edge - 304 stainless steel, single bin, #4 belt over chain, 13 cm (5 in.) feedgate |

| 4852 | DS30 G4 Edge - 304 stainless steel, MultApplier (dual bin), #4 belt over chain, 13 cm (5 in.) feedgate |

| 400R and 600R dry spinner spreader | |

| New Leader G5 - | |

| 4854 | DS20 G5 - 304 stainless steel, single bin, #4 belt over chain, 28 cm (11 in.) feedgate |

| 4856 | DS20 G5 - 304 stainless steel, single bin, #4 belt over chain, 13 cm (5 in.) feedgate |

| 4858 | DS20 G5 - 304 stainless steel, MultApplier (dual bin), #4 belt over chain, 13 cm (5 in.) feedgate |

| 4862 | DS30 G5 - 304 stainless steel, single bin, #4 belt over chain, 13 cm (5 in.) feedgate |

| 4864 | DS30 G5 - 304 stainless steel, MultApplier (dual bin), #4 belt over chain, 13 cm (5 in.) feedgate |

New Leader is a trademark of Highway Equipment Company.

Spread width up to 32 m (105 ft) with the DS20

Spread width up to 32 m (105 ft) with the DS20

DS30 Dry Spinner Spreader

DS30 Dry Spinner Spreader

The DS20 and DS30 provide up to 32-m (105-ft) spread widths and the adjustable spinner assembly allows for quick, accurate settings during variable-rate applications, broadcasting materials farther and wider with consistent spread patterns, and producing industry-leading productivity.

Depending on the model of Dry Spinner Spreader, you can achieve spread widths from 18.92 to 27.43 m (60 to 90 ft), but with the increased clearance of 1.74 m (68 in.) the 400R and 600R Dry Spinner Spreader can achieve spread widths from 21 to 32 m (70 to 105 ft). Added spread width increases the number of acres per day and decreases the number of passes, which also reduces fuel costs and compaction.

By maintaining spread width, operators can consistently place product throughout the fields and prevent bottlenecking of product at the row end.

With a full spread pattern and reduced overlap through integrated technologies such as AutoTrac™ automated steering and John Deere Section Control, the 400R and 600R Dry Spinner Spreaders allow for full product coverage while reducing input costs from overlap.

Additionally, by combining the John Deere 400R or 600R Dry Spinner Spreader chassis and the New Leader dry spinner spreader, operators can maintain spread widths even when rpms are reduced. John Deere's pressure-and-flow-compensated hydraulics allows operators to maintain spinner speed throughout each pass, while maintaining consistent spread width and pattern. This added height allows a greater trajectory at a lower spinner speed and has the ability for later season applications.

NOTE: With differences in fertilizer density, size, and crush strength a spread pattern test is the only way to measure a product's true spread width and pattern.

New Leader is a trademark of Highway Equipment Company.

Experience fuel saving and noise reduction with CommandDrive

Experience fuel saving and noise reduction with CommandDrive

With the CommandDrive powertrain, save fuel, reduce cab noise, get improved traction in challenging conditions, and cover more acres per day. CommandDrive offers the operator an Auto Mode that automatically directs the engine to run at the lowest rpm necessary to maintain ground speed and hydraulic functions and to meet the demands of the solution system.

CommandDrive also allows operators to adjust the aggressiveness of acceleration and deceleration and features an Auto Idle system that reduces engine speed to 900 rpm when the machine is in park. It all adds up to:

- 20 percent or greater fuel savings

- More acres sprayed per day, thanks to fewer fuel stops and improved traction in rough conditions

- Reduced in-cab noise levels by 3to 5 decibels

- Fewer demands on the operator

CommandDrive is base equipment on all 408R, 410R, 412R, 612R, and 616R Sprayers, as well as 400R and 600R Dry Spinner Spreaders.

StarFire 7000 Integrated Receiver on John Deere 400 and 600 Series Sprayers and 800R Floaters

StarFire 7000 Integrated Receiver on John Deere 400 and 600 Series Sprayers and 800R Floaters

The StarFire 7000 Receiver is the latest addition to the suite of Precision Ag Technology from John Deere. The StarFire 7000 Receiver offers greater accuracy, faster pull-in times, and season-to-season repeatability. This means less hardware, faster times recovering from a shading event, and the confidence that your guidance lines and boundaries do not shift from year to year. The integrated design further enhances the value that you have come to expect from StarFire products.

Similar to the StarFire 6000 Integrated Receiver, the StarFire 7000 eliminates all setup, installation, and calibrations. There is no need to verify machine and receiver measurements, as this has been done precisely for you at the factory. You will spend 60 minutes less per receiver move each season, which gives you more time to focus on other parts of your operation.

With updated Ethernet connectivity, software updates are easier and faster. StarFire 7000 Integrated Receiver maintains the speed to update software in under 4 minutes while remaining in the cab. Over-the-air updates are 85 percent faster with the StarFire 7000 Integrated Receiver because of Ethernet connectivity.

Order codes

Code |

Attachment |

Description |

188H |

|

StarFire Ready, Less Receiver |

188T |

|

StarFire Universal Receiver with SF1 |

1890 |

|

StarFire Universal Receiver with 1 year SF-RTK License |

189B |

|

StarFire Universal Receiver with RTK Permanent License |

Benefits to the StarFire 7000 with SF-RTK

- 5-year repeatability

- 10-minute pull-in time

- 2.5-cm (1-in.) pass-to-pass accuracy

- Drop-in replacement for StarFire 6000 Integrated Receivers

To learn more about the StarFire 7000, visit the StarFire 7000 page.

Model year 2022 and newer Ultimate lighting

Model year 2022 and newer Ultimate lighting

Model year 2021 4 Series LED lighting

Model year 2021 4 Series LED lighting

When you’re staring down a string of 2,000-acre days, your equipment isn’t all that needs to be operating at peak – your operators need to be at their best, too. That’s why John Deere put together a range of cab packages to give you just the right features to keep your operators comfortable and efficient.

For corner-office comfort that can help make short work of the longest days, take a look at the Ultimate Comfort and Convenience package. The heated, ventilated ActiveSeat™ II isolates the operator from up to 90 percent of vertical movement and comes in leather with massage functions. The Ultimate package also gives you a premium XM® ready sound system with subwoofer, a leather-wrapped steering wheel, a refrigerator, and more.

When the long days turn into long nights, you’ll be glad you ordered the Ultimate Visibility package. A full 360 degrees of powerful light-emitting diode (LED) cab lighting gives you a clear view all around the machine, while eight LED service lights illuminate critical service areas.

The following table gives a quick reference of what is contained in the Visibility packages.

|

Feature |

Premium Visibility package |

Ultimate Visibility package |

Cab |

Halogen work lights (cab roof) |

--- |

--- |

LED work lights (cab roof) |

Six |

Six |

|

LED beacons (cab roof) |

Two |

Two |

|

LED convenience lights |

Eight |

Eight |

|

Front sunshades |

X |

X |

|

Right-side sunshades |

X |

X |

|

Rear sunshades |

X |

X |

|

Front wiper |

X |

X |

|

Right-side wiper |

X |

X |

|

Vehicle |

Halogen work lights (vehicle) |

--- |

--- |

Halogen hood work lights |

--- |

--- |

|

Halogen high beam (hood) |

--- |

--- |

|

Halogen low beam (hood) |

Two |

Two |

|

LED high beam (hood) |

Two |

Two |

|

LED work lights (vehicle) |

Six |

Six (two of these are higher, 4400-lumen output lights) |

|

LED hood work lights |

Four |

Four |

|

LED beacons |

One rear |

One rear |

|

Boom LED lights |

Two |

Two |

|

Boom halogen lights |

--- |

--- |

|

Manually adjustable left-hand and right-hand boom mounted with bubble mirror |

X |

X |

|

Manually adjustable right-hand cab |

--- |

--- |

|

Electrically adjustable and heated right-hand cab |

X |

X |

|

Manual underframe mirror |

--- |

--- |

|

Electrically adjustable and heated underframe mirror |

X |

X |

|

Additional camera ready |

X |

--- |

|

Left-hand and right-hand side view camera ready |

--- |

--- |

|

Integrated backup camera |

X |

X |

Ultimate Comfort and Convenience cab

Ultimate Comfort and Convenience cab

In addition to the Visibility packages available, the following table gives a quick reference of what is contained in the Cab Comfort and Convenience packages.

| Select Comfort and Convenience package | Ultimate Comfort and Convenience package | |

| Cloth seat | X | --- |

| Leather seat with carpeted floor mat | --- | X |

| ActiveSeat™ II | --- | X |

| Heated and ventilated leather seat with massage functionality | --- | X |

| Mechanical fore/aft and lumbar support | X | --- |

| Electronic controls and pneumatic lumbar support | --- | X |

| Adjustable right-hand CommandARM™ controls with integrated CommandCenter™ touchscreen display | X | X |

| 24-degree right-hand seat swivel and 8-degree left hand seat swivel | X | --- |

| 24-degree right-hand seat swivel and 24-degree left-hand seat swivel | --- | X |

| AM/FM Aux and Bluetooth® wireless inputs plus two cab speakers | X | --- |

| 16.5-cm (6.5-in.) touchscreen radio, XM ready, and 6.1 speaker system with subwoofer including AM/FM Aux with Bluetooth™ wireless inputs | --- | X |

| Automatic temperature controls with controls located on CommandARM | X | X |

| Footrests | --- | X |

| Business band ready | X | X |

| Refrigerator | --- | X |

| Four USB and one 12-V outlet | X | X |

| Right-hand accessory rail | --- | X |

| 120-V outlet | --- | X |

| Leather-wrapped steering wheel | --- | X |

Some of the features in the chart above are also available as attachments. There are also many options for mounting a variety of monitors, tablets, and phones.

*NOTE: Bluetooth where certification allows.

Bluetooth is a trademark of Bluetooth SIG, Inc. XM is a trademark of Sirius XM Radio, Inc.

NOTE: Not available on sprayers ordered as dry box only.

John Deere Signature Edition badge

John Deere Signature Edition badge

To make the most powerful John Deere options available in one cost-effective package, 408R through 616R Sprayer models can be ordered as John Deere Signature Edition. Marked with an exclusive badge only available on the Signature Edition, this package includes:

- Ultimate Comfort and Convenience package

- Ultimate Visibility package

- ActiveSeat™ II equipment

- JDLink™ 5-year subscription

- Premium 3.0 or Automation 4.0 activation

- 4G LTE connectivity hardware

- Automatic Solution Control*

- BoomTrac™ Pro 2*

- ExactApply™ system*

Get all the top-of-the-line comfort features and technology options in one special edition: The John Deere Signature Edition.

For any additional mounting needs, there are part solutions available through John Deere to resolve unique mounting configuration needs.

*NOTE: Automatic Solution Control, BoomTrac Pro 2, and ExactApply system are not available on the 400R and 600R.

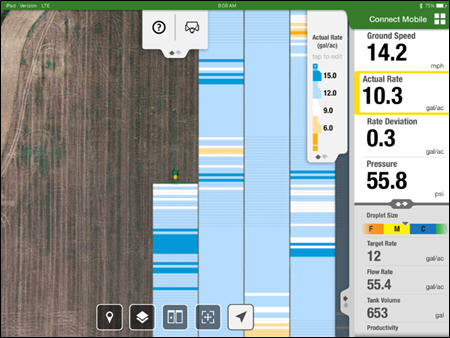

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile actual rate map and pressure map in split screen gives the operator deeper understanding of machine performance

Connect Mobile overview

John Deere Connect Mobile is a solution that utilizes an Apple® iPad® tablet in the cab that provides the operator a better understanding of the sprayer’s performance. Connect Mobile documents and displays several sprayer performance attributes, helping the operator monitor and more easily detect problems that can occur while spraying. Connect Mobile also has a common user interface that makes it easy to use between different pieces of John Deere equipment. Once the job is done, the iPad with the spraying data can be utilized to perform basic crop scouting activities in the field.

Spraying attributes

Monitor key performance indicators in map layers and dashboard tiles such as:

- Actual rate

- Rate deviation

- Pressure

- Ground speed

- Droplet size

- Target rate

- Flow rate

- Tank volume

- Productivity

- Fuel rate

In base equipment

Connect Mobile hardware is factory installed on all model year 2022 and newer 408R, 410R, 412R, 612R, 616R, 400 and 600 Series Sprayers and dry machines as well as model year 2017 to 2021 R4030, R4038, R4044, R4045, and R4060 Sprayers, making it easy to get started with Connect Mobile.

Learn more about Connect Mobile in the Field and Crop Solutions section within the Precision Ag Technology product line and how it can improve the quality of a spraying job.

iPad and Apple are trademarks of Apple Inc.

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

Specs & Compare

Key Specs | 600R Current Model |

| Engine | |

| Rated engine power | 280 kW 375 hp |

| Maximum engine power | 309 kW 415 hp |

| Transport speed, maximum | 56.3 km/h 35 mph |

| Spread speed range | 0 to 40.2 km/h 0 to 25 mph |

| Dry compatible | Yes: 5.7 or 8.5 m3 200 or 300 cu ft |

| Spread system type | |

| Suspension | Dual-strut independent wheel air-ride suspension |

| Crop clearance with standard tires | 147.3 cm 58 in. |

| Weight (empty) | With DS30: 14,375 kg 31,691 lb |

Engine | |

| Make | |

| Rated engine power | 280 kW 375 hp |

| Maximum engine power | 309 kW 415 hp |

| Emissions | Final Tier 4 (FT4) |

| Number of cylinders | Six |

| Displacement | 9.0 L 549 cu in. |

| Alternator | 250 amp |

| Fuel tank capacity | 565 L 149.2 gal. |

| Diesel exhaust fluid (DEF) tank capacity | 29.5 L 7.8 gal. |

Drivetrain | |

| Type | Hydrostatic |

| Drive | Full-time, four-wheel drive (4WD) |

| Shifting | Electrohydraulic |

| Hydraulic reservoir capacity | 98.4 L 26 gal. |

| Spread speed range | 0 to 40.2 km/h 0 to 25 mph |

| Transport speed, maximum | 56.3 km/h 35 mph |

Chassis | |

| Dry compatible | Yes: 5.7 or 8.7 m3 200 or 300 cu ft |

| Suspension | Dual-strut independent wheel air-ride suspension |

| Crop clearance with standard tires | 147.3 cm 58 in. |

| Front tires | 380/105 R50, 420/95 R50, or 480/80 R50 |

| Rear tires | 380/105 R50, 420/95 R50, or 480/80 R50 |

| Flotation tires | 620/70 R46 or 800/55 R46 |

| Hydraulic tread adjust | Standard |

| Wheel tread spacing | 305 to 406.4 cm 120 to 160 in. |

| Wheelbase | 430 cm 169.3 in. |

| Turning radius | 9.2 m 30.2 ft |

| Parking brake | Spring-engaged, hydraulically disengaged wet disk pack |

| Primary brakes | Hydrostatic |

| Ladder raise/lower | Automatic |

| Weight (empty) | With DS30: 14,375 kg 31,691 lb |

Drybox | |

| Drybox model | |

| Drybox material | |

| Spread width | |

| Flow rate | |

| Product spread | |

| Conveyor belt type | |

| Covering tarp | |

| Protection grates | |

| Concentrated lubrication points | |

| Scale | |

Spread system | |

| Type | |

| Spreader calibration | |

| Fertilizer spreading | |

| Spreader options | |

| Variable rate compatible | |

| Feedgate | |

| Endgate | |

Additional information | |

| Date collected | 1 March 2021 |