John Deere SS12P Series

Pendular Spreaders

- Field installed agitator kit available

- Spreader spout provides precision spreading

- Drive system has anti-wear, cast-steel gearbox

- Rubber insert conversion kit keeps discharge from clogging

Features

Superior corrosion resistance

Superior corrosion resistance

The reinforced fiberglass hopper on the 12 Series Pendular Spreader provides superior corrosion resistance, resulting in stronger durability and longer wear life.

It has a frame made of sturdy, tubular steel and is painted with polyester resin powder coat for added corrosion resistance.

Standard spout

Standard spout

Frontier™ Pendular Spreaders are designed to provide a precise spread. To accommodate this, they can be outfitted with various spreader spouts.

The spreader spouts are made of nylon and reinforced fiberglass for corrosion resistance and increased durability.

By simply rotating the optional directional spout's tip, an easy spread adjustment can be made to the left only, to the right only, or to the middle.

Optional left/right directional attachment

Optional left/right directional attachment

Optional left/right directional attachment

Optional left/right directional attachment

Cast-steel gearbox provides extended durability

Cast-steel gearbox provides extended durability

The 12 Series Pendular Spreader comes standard with a 540-rpm PTO, Category 1 driveline. Its heavy-duty shielded shaft, made in compliance with American Society of Agricultural and Biological Engineers (ASABE) requirements, is built to last and ensures operator safety.

The anti-wear, cast-steel gearbox operates in oil bath, providing a longer life and durability for the drive system.

All the field conversion agitator kits listed below allow operators to use multiple types of seed or fertilizer without clumping up.

Deflector shield conversion kits for broadcast spreaders ensure that material is thrown where the operator chooses.

Side-row discharge conversion kits for broadcast spreaders focus the spread to the side of the tractor.

The left-right direction attachment concentrates material to specific areas when using pendular spreaders.

A salt and sand spout kit and an optional locking nut are also available.

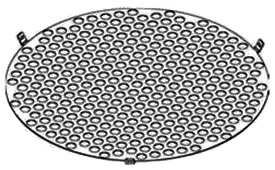

Filter grate drawing from operator's manual

Filter grate drawing from operator's manual

The filter grate kit is used when loading SS1079P, SS1116P, SS1180P, and SS1220P Pendular Spreaders. It keeps hard and clumpy material from damaging parts or clogging the spreader.

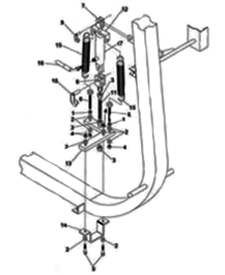

Hydraulic gate control drawing from operator's manual

Hydraulic gate control drawing from operator's manual

The hydraulic gate control kit is used to open and close the gate of the spreader without the operator having to get off the tractor by using the tractor's hydraulic system.

The field-installed rubber insert kit is used to keep the discharge from clogging.

Specs & Compare

Dimension | SS12P Series Current Model |

| Hopper width | |

| Hopper loading height | 119.4 cm 47 in. |

Weight | |

| Hopper capacity | 1000.2 kg 2205 lb |

| Machine | 155.6 kg 343 lb |

| Shipping (per pair) | 195 kg 430 lb |

Hopper | |

| Volume capacity | 1.2 m3 42.4 cu ft |

| Material | Reinforced fiberglass |

PTO | |

| rpm | 540 rpm |

| Tractor hp range | 14.9-44.7 kW 20-60 hp |

| Shaft category | |

Range | |

| Swath spread | 5.2-14.3 m 17-47 ft |

Hitch | |

| Type | 3-pt, Cat. 1, Cat. 2 |

| iMatchTM compatible | |

Set-up time | |

| Labor hours | 0.5 hours |

Warranty | |

| Time period | One year |

Additional information | |

| Date collected |